The tea farm is characterised by a high stock of old trees and grows new tea plants from its own seedlings.

For the production of Liu Bao, the leaves are spread out on flat bamboo racks after harvesting and air-dried there. This is followed by cha qing, which is also typical of other Chinese teas, in which the leaves are heated in an oven to prevent further oxidation. The ovens rotate to ensure that all the leaves are evenly mixed. In the next step, the leaves are rolled, giving them their special shape, and then dried. After this step, in a sense, a green tea is in front of us.

The next step is stylistic for Liu Bao and makes it a post-fermented Heicha. This is followed by wo dui, the "layering" of the leaves and moistening with water. Depending on the temperature, the leaves are also covered with blankets to create a particularly warm, humid climate. Over a period of 12 hours, the leaves are now fermented in this environment. In this process, the leaves change significantly, becoming darker and also softer.

After fermentation, the leaves are heated and then pressed several times and laid out loose again. In the following step, the tea is then traditionally pressed into baskets made of bamboo, in which it is left to mature for the next period of time. Bamboo wood has historically been used to store tea in China, as it holds the tea tightly together (conducive to an even ripening process) and also allows necessary air circulation. Bamboo wood is also used for Pu Erh to hold several of the teas together.

Liu Bao tea is not sold until at least one year after storage, as only then can a fully mature flavor profile develop. Longer aged Liu Bao, like this one, are still characterized by an intensified, fuller flavor profile.

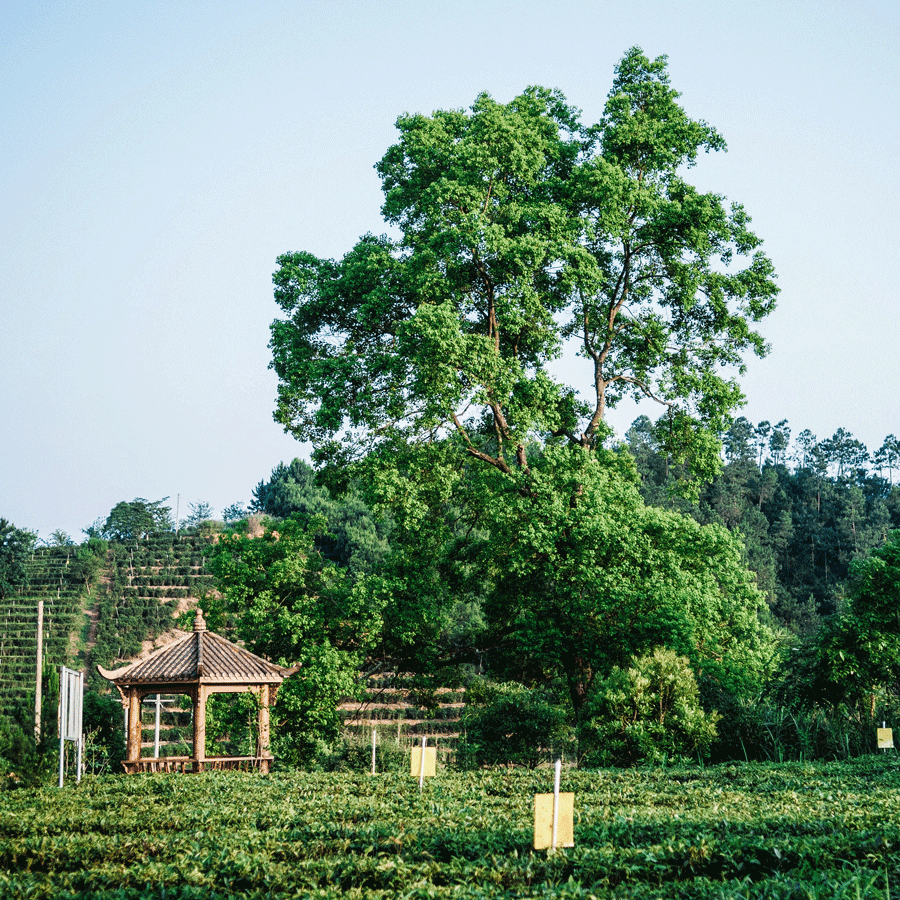

Particular to this high-quality Liu Bao is the producing farm, which has a proven commitment to growing without chemical pesticides. The majority of Liu Bao farms today unfortunately resort to synthetic means in the cultivation of their tea, which is why our farm is a positive exception.