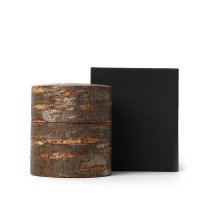

For the production of traditional kabazaiku (樺細工), master craftsmen search for the best trees in spring when the cherries are in blossom and mark them to make them easier to identify for harvesting in autumn. After the heavy rains at the end of summer, the bark is soft and elastic and can be cut from the trees in strips. Since the tree regenerates the bark and is only harvested one more time, this method is considered very sustainable. Before processing, the bark is dried naturally for about two years and finally polished with sandpaper for a smooth, even surface. To make it, thin slices of cherry bark and wood are glued together with natural glue and then pressed around a mould or onto a base with a hot trowel. Once sanded and waxed, the cherry bark reveals a rich reddish-brown hue and a refined sheen that deepens with use.

Chazutsu made from the bark of wild cherry trees are called kabazaiku (樺細工) and are fabricated in the famous craft village of Kakunodate, in the Akita Prefecture. They are highly coveted for their natural beauty and the great craftsmanship of the master artisans. Moreover they are considered to be the best way to store a wide variety of teas.

Historically, kabazaiku were mainly made by lower samurai who earned an additional income in the former samurai stronghold of Kakunodate.