Traditional Production Method

Our producer is characterized in particular by the fact that he trusts in the original, traditional production methods. In many aspects, these methods are significantly more complex and time-consuming than the more quantity-oriented modern methods of most Oriental Beauty farms, but they also produce a superior, maximally natural tea in terms of quality and taste. Particular attention is paid to the right time of harvest, strict leaf selection and particularly rapid, detailed processing.

Hand-Picked Harvest

Harvesting usually begins around the time of the Chinese Dragon Boat Festival in late May/early June. It requires the utmost concentration of the workers just to pick out the bitten buds and pairs of leaves, which in the case of the Oriental Beauty cultivar are also very small. There is also great time pressure, because the bitten leaves should be picked within 7 days after the bite. Otherwise you would lose a lot of flavor and taste. Affected leaves are characterized by their light yellow color and slightly twisted shape and have a highly aromatic sweet smell. The higher the proportion of these leaves in the end product, the higher the quality of the tea is rated in the end. Our Oriental Beauty consists exclusively of leaves of the highest category. Only 1 - 1.5 kg of tea is produced by our tea farmer per day due to strict leaf selection.

Natural Withering

After harvesting, the tea leaves wither. Unlike common Taiwan Oolongs like High Mountain or Bao Zhong, the delicate Oriental Beauty leaves are not exposed to direct sunlight. This would affect the natural sweetness of the tea. Instead, the leaves are laid out on bamboo mats in the shade and gently dried.

Controlled Oxidation

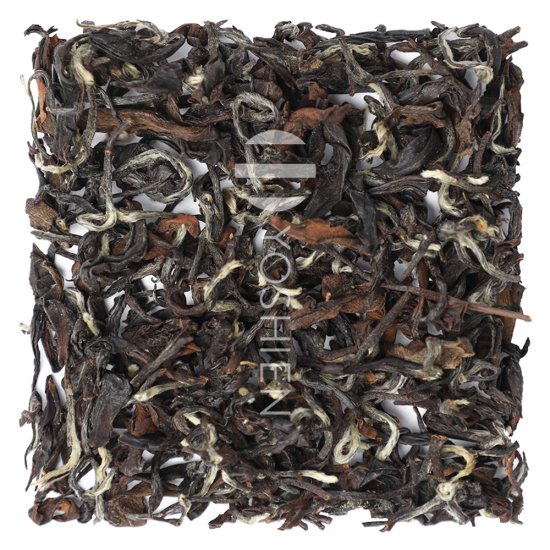

Once they have lost sufficient moisture and strength, oxidation of the leaves takes place. In this process, the plant cells are broken up by intensive agitation, allowing the plant's own enzymes to escape to the outside. These react with the surrounding oxygen and cause a slight red coloration of the leaves. This is also accompanied by a change in taste: the leaves become sweeter. Oxidation takes place in 3 steps: Two times for 3 minutes each, the leaves are skillfully shaken by hand on the bamboo mats. A final "pouring" is then done by machine for 20 minutes. As is typical for Taiwan Oolong, the leaves are then wrapped in a cloth and pressed tightly together. During this process, the cell sap of the leaf comes out and mixes with the surface of the other leaves. The leaves remain wrapped in the cloth for up to one hour.

Gentle Drying

Finally, the leaves are gently dried in an oven at 80 degrees Celsius for 3 hours. At least now you can see the white tips in the middle of the deciduous brown leaves. The white tips are the aromatic leaf buds of the tea plant, the number of which in the tea is another important quality indicator.