The tea cultivation area around Luye in Taitung is the largest in eastern Taiwan. It is advantageously located at the southern end of the East Rift Valley between the mountains of the Taiwanese Central Mountain Range (中央山脈) and the Hai'an Range (海岸山脈) near the Pacific coast. At 350m above sea level, the tea farm sits at an ideal location with high average rainfall as well as excellent drainage. As a result of these conditions, the teas in Luye can be harvested 1 month earlier in the spring and 1 month later in the winter than High Mountain oolongs. These teas thus have a distinctive taste from High Mountain variants and are enjoyed across Taiwan.

The famous Jin Xuan cultivar (Taiwan Tea var. 12, a.k.a. Golden Day Lily) is used for our Milk Oolong. This robust and high-yield cultivar is the result of hybridisation and has become popular in both Taiwan and Thailand since 1980. The floral and mildly sweet milky taste of this cultivar, however, best unfold when grown at lower elevation.

Our Milk Oolong is a pure product with no additives or artificial flavours. Some generic Milk Oolongs add aroma to intensify the taste or compensate for lower quality tea, but our teas are all natural.

For oolong teas, typically the bud and first three leaves are harvested by hand. These leaves are typically allowed to grow a bit larger than other teas such as green tea. After harvest the leaves are set out to wither in the sun, which begins the oxidation and fermentation processes as the leaves dry. Thereafter the leaves are brought indoors to continue withering where they are repeatedly moved about. Small tears in the leaves, especially at the edges, allow juice from the leaves to seep out and oxidise.

During the next stage the leaves are laid out on either bamboo plates or large nets and placed in a fermentation chamber. The leaves are monitored until the tears in the leaves turn reddish-brown as a marker of fermentation.

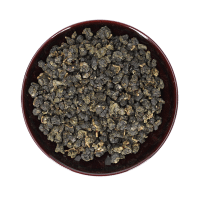

Once the desired degree of fermentation has been reached, further oxidation and fermentation are halted with heat in an oven (kill green). Thereafter the leaves are broken up in a rolling machine so that the remaining leaf juice comes out and coats the outside of the leaves. The tea is then rolled, partially by hand and partially by machine (Ball Cloth Rolling, Baorou 包揉), to attain its characteristic half-rolled form. In the last stage the tea is placed in the oven to dry.