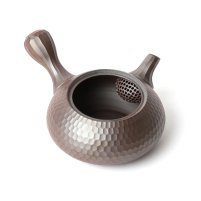

Clay

Natural, purple clay (shidei 紫泥).

Ikomi/Rokuro

The components of the lid and jug are hand-potted on the potter's wheel and then assembled for a perfect fit (rokuro 轆轤).

Strong Reduction Firing (Kyo-kangen Shosei 強還元焼成)

When firing ceramics, various processes start as the temperature rises. First, the water still left in the body evaporates. Above a temperature of 500°C, the clay is completely dehydrated and its chemical state is irreversible. The organic components burn and oxidation takes place. After solidification, the vitrification phase begins.

Reduction firing of the ceramic produces an excess of carbon and a reduction of oxygen in the kiln. Carbon monoxide extracts oxygen from the surroundings and the body. A strong smoke development is the result. The body changes colour, from light grey to black, depending on the intensity and time of the reduction. The clay has less oxygen, becomes firmer and more solid and at the same time acquires greater porosity. All in all, this leads to the specific properties of a kyusu fired in this way when preparing green tea in terms of taste and effect. After firing, the special clay, which is rich in minerals, reacts in a characteristic way with the ingredients of the tea and the water (see the tab on tea varieties).

Glaze

Unglazed (yakishime 焼き締め).